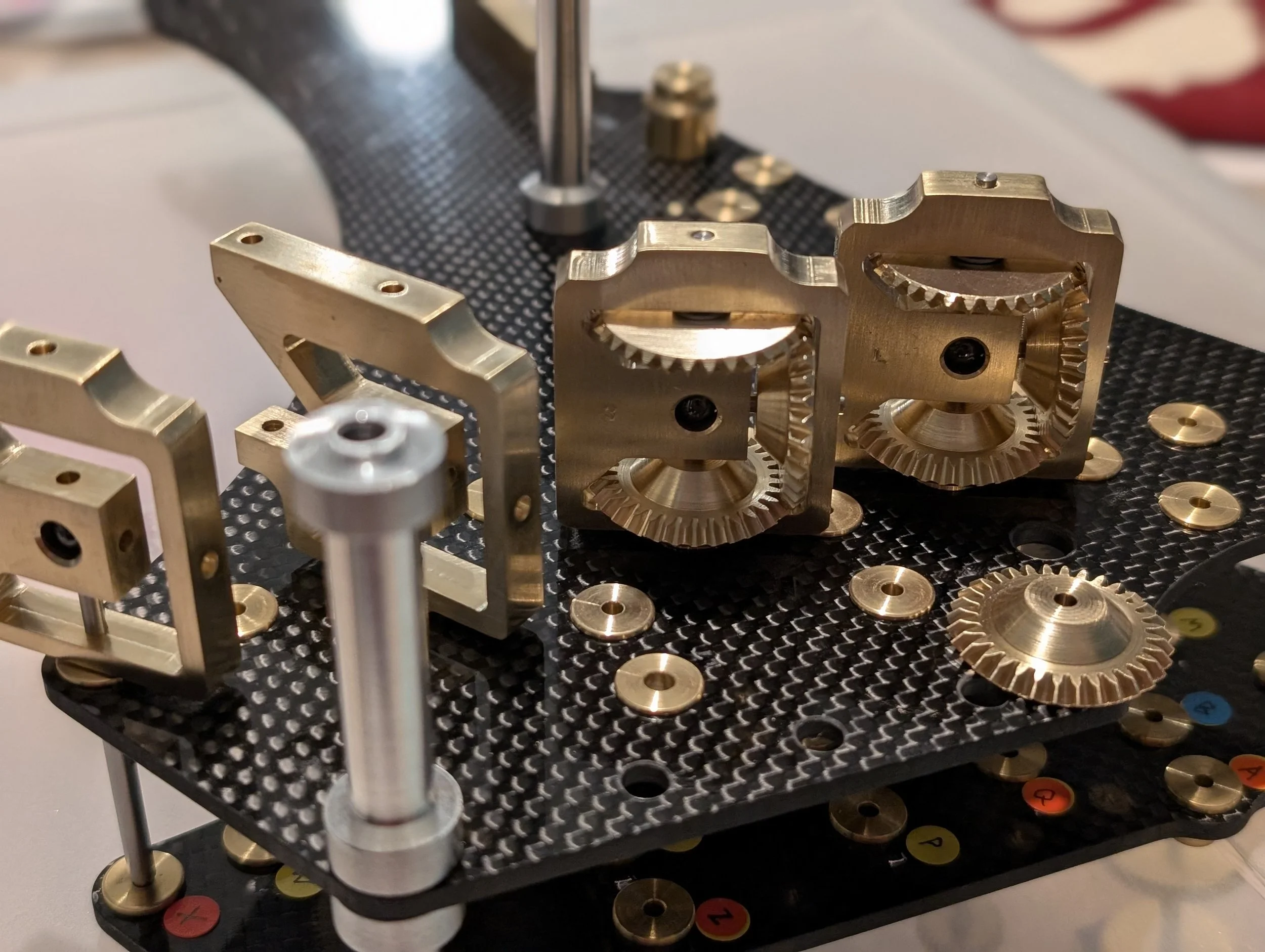

Calculation Differentials

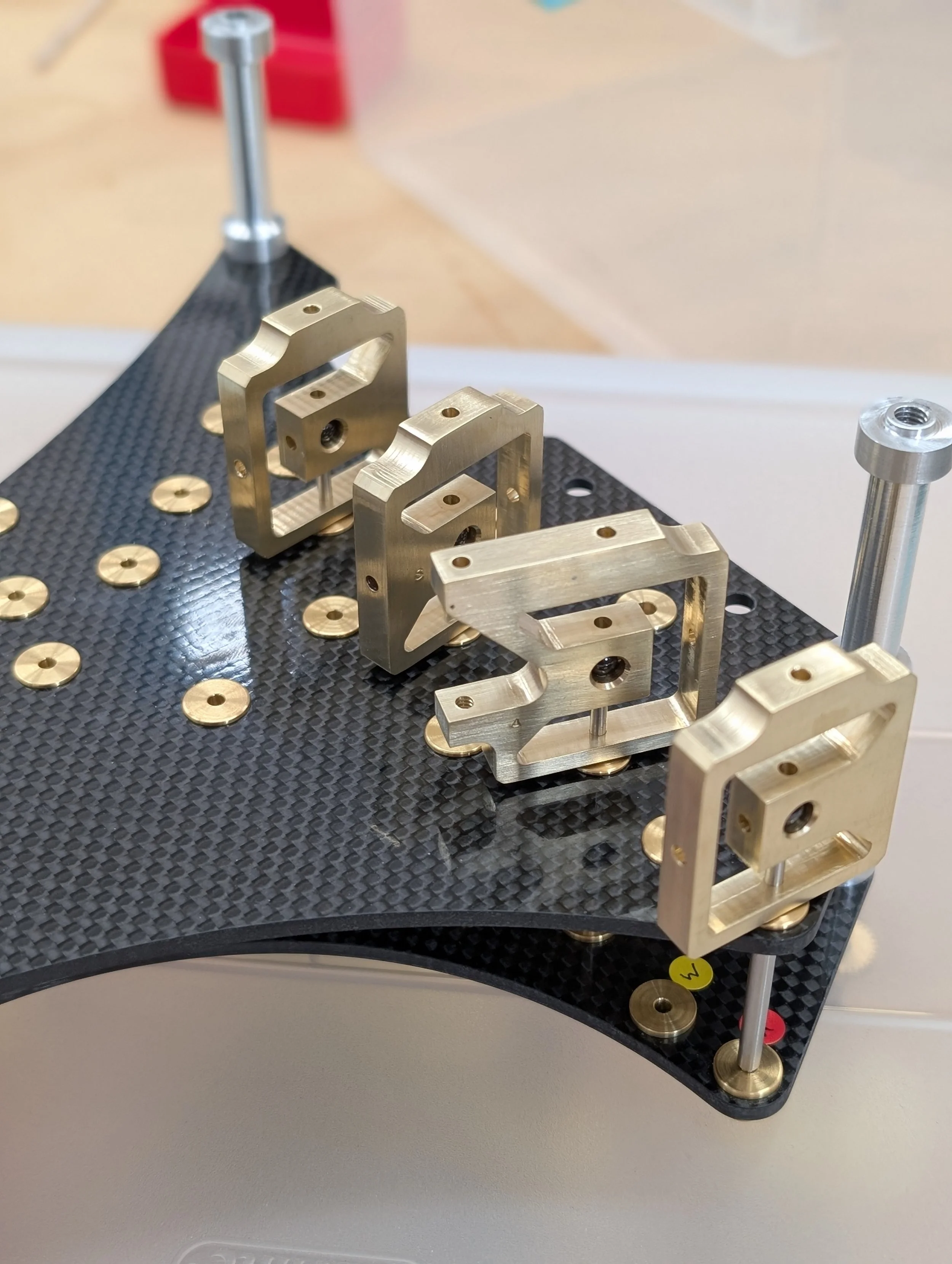

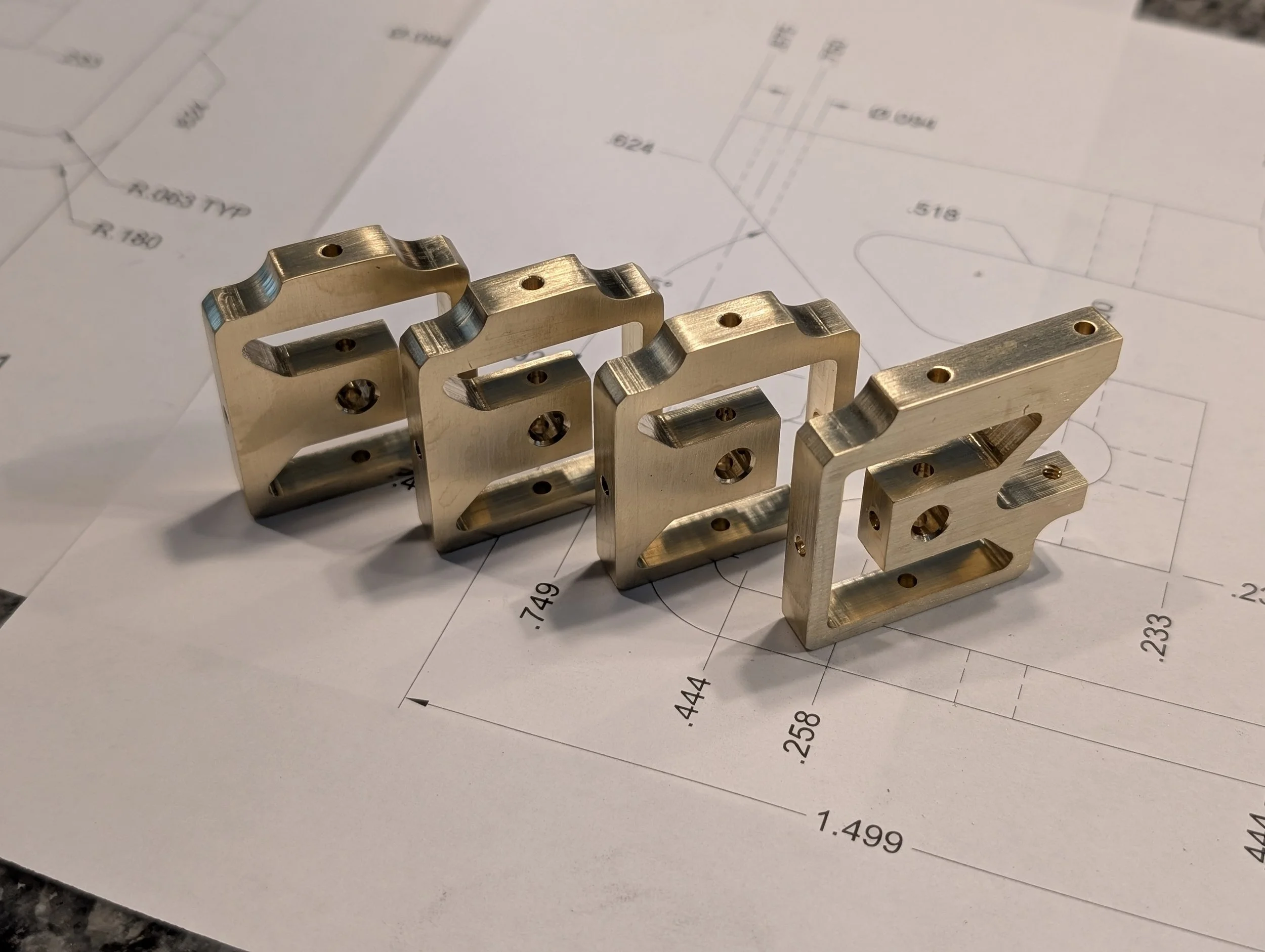

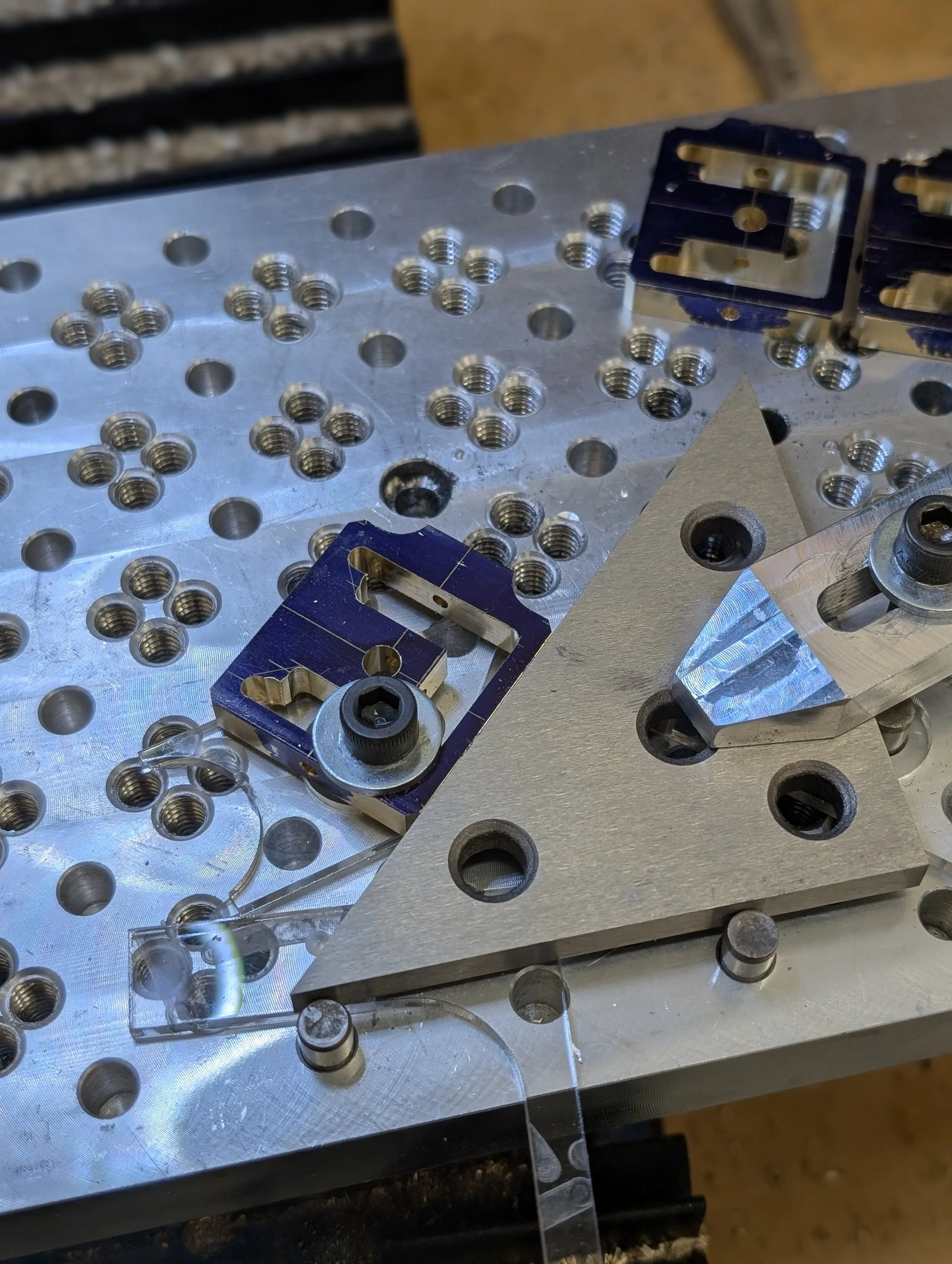

This is a part I’ve been dreading…the four differentials with three bevel gears each. The gears were a bit of a trudge, but otherwise this section was not as bad as I feared. The frames were all laid out with layout blue and scribe lines, then the DRO used to drill all the corners of the cutouts. Then the mill for milling to the scribe lines, with just the minor annoyance of some 45 deg cuts needing to be done on the fixture plate. This approach worked excellently, I’m always surprised that working to scribe lines easily yields .005” class accuracy, and .002” with magnification and care.

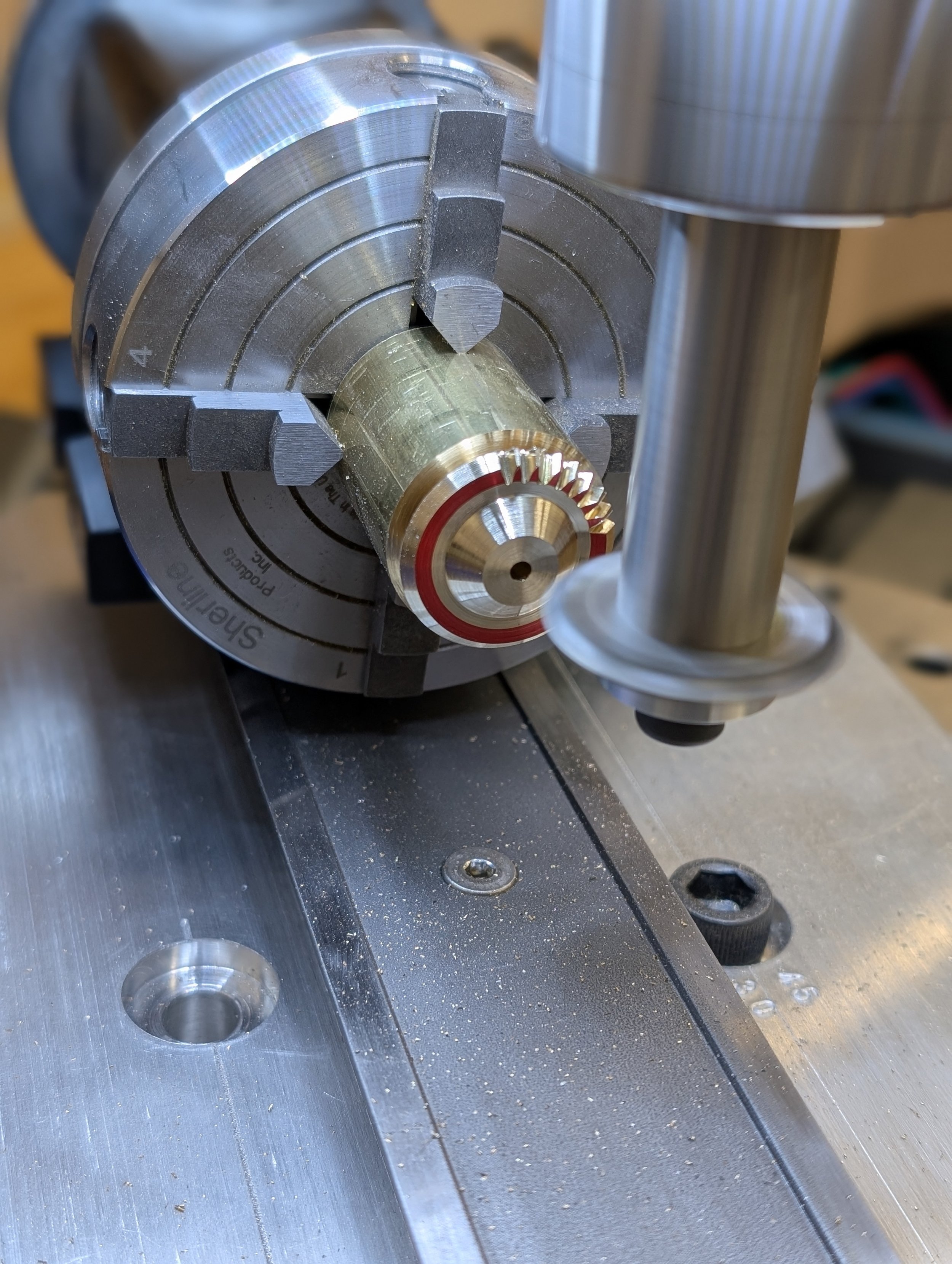

The gears were very much repetition and plenty of it. 32 teeth, needing multiple passes for flanking the tapered teeth, 12 gears… it was a lot of cranking the mill handwheel back and forth and I’m glad to be done. I made a mistake on the first attempt but otherwise everything went to plan.

Next will be the various arms and linkages, especially with the (slightly different) apsidal differential that needs an integrated sheave. The reason for this is that the lunar apsidal motion is so great in magnitude that the action on the differential needs to be much closer to the center than the others, so close that it is easiest to just make the pivot part of the frame rather than out on an arm.