Machining

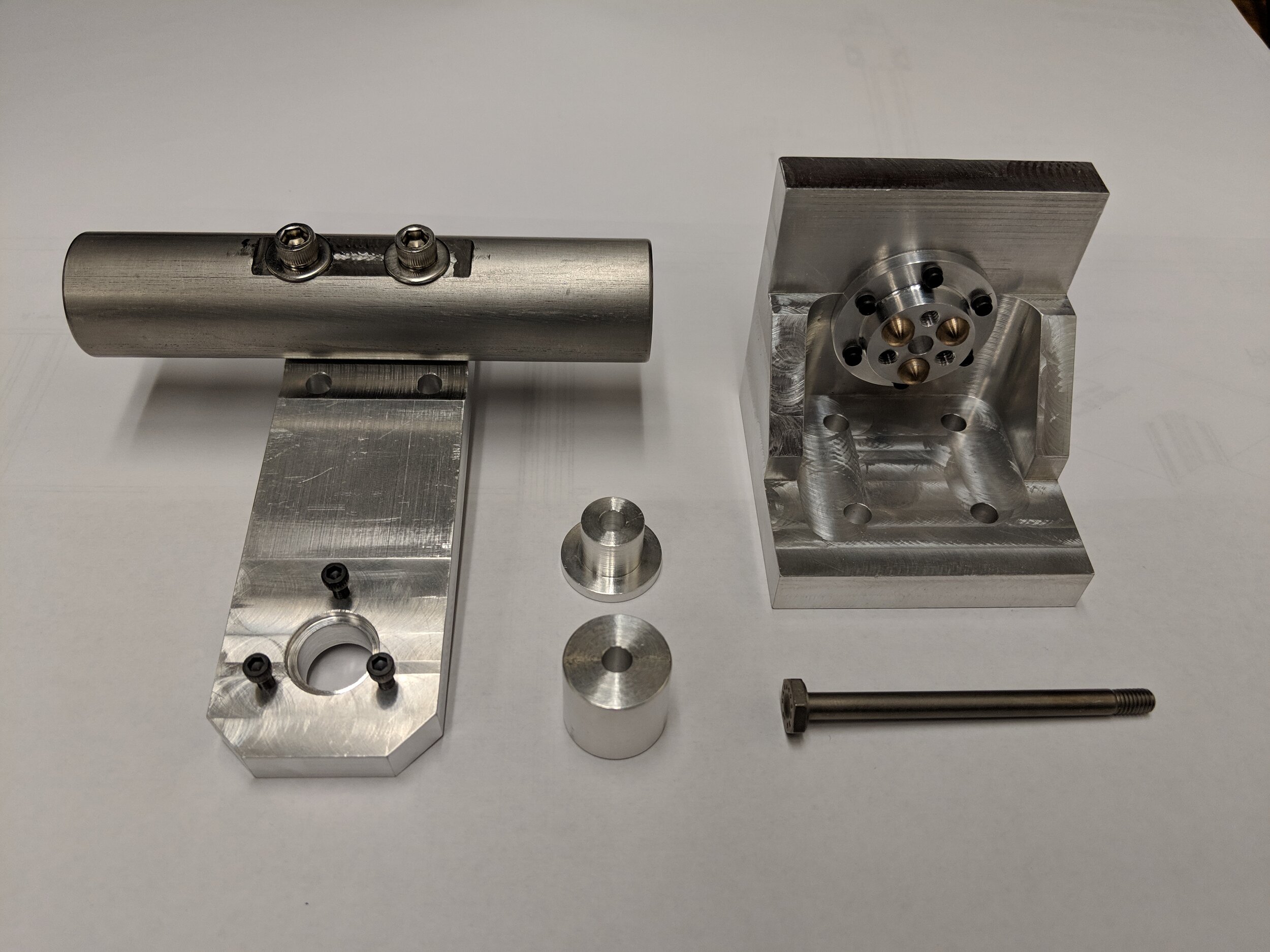

Turning

Turned parts are generally rotationally symmetric about an axis and are machined on a lathe. We operate two lathes to accommodate a range of part sizes from 1/16-9 inch (1.5-230mm) in diameter and up to two feet long.

Milling

Milled parts tend to be more rectangular, or may have arcs. We operate a DRO-equipped manual minimill with a 5x11 inch (130-280mm) working envelope. Mills can also make very accurate patterns of holes and extremely flat surfaces.