Escapement Testing - Weight Redistribution

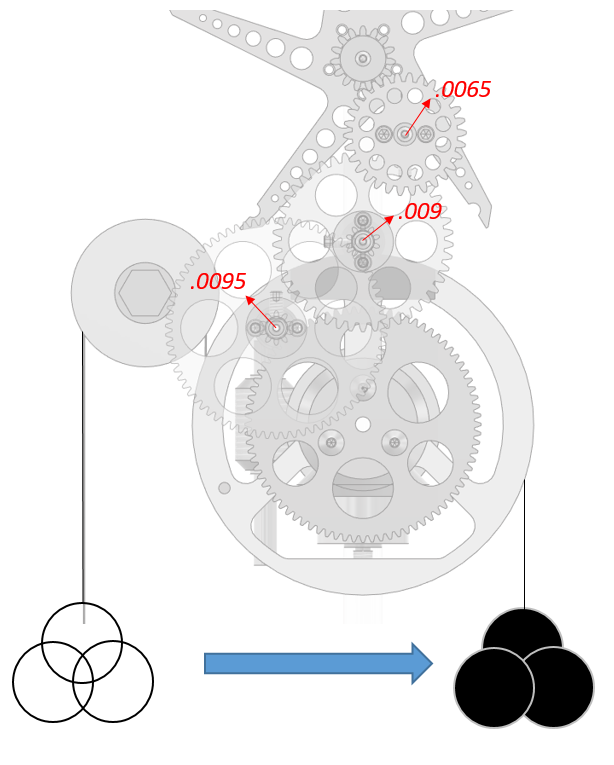

I have made an adjustment to the gear depthing at the 10T:80T joint but shifting the midplate bracket slightly. I have also experimented with shifting some weight to the direct (downwards pulling) side of the drive wheel. This causes significant deflection in the gear train as shown below and changes the gear engagements as a result. The design original called for a weight distribution between the two locations to be adjustable, however I’m finding that the clock runs most consistently with all the weight on the upwards pulling side. Overall variation is at 48 ms (1σ) vs 61 ms (1σ).

Data with all weight pulling upwards

Data for same weight, but 1/3 shifted to downwards pulling side. Overall variation goes up and the 6-Tick pattern (middle right plot) gets stronger

More information on NAWCC Forum post on this subject: